The Intelligence of Metal Recovery: Implementing Google’s CircularNet and Cloud Ecosystem

- RameshDharmaraj

- 4 days ago

- 3 min read

Updated: 1 day ago

This guide outlines the technical roadmap for building an AI-powered system to identify unwanted contaminants in metal recycling streams. By combining Google's CircularNet models with the infrastructure of Google Cloud and the spatial intelligence of Google Maps, recycling facilities can transform manual sorting into a high-precision, data-driven operation.

1. The Core Engine: Understanding CircularNet

CircularNet is an open-source machine learning model developed by Google specifically to address waste identification challenges. Unlike general object detection models, it is trained on thousands of real-world images from Material Recovery Facilities (MRFs), enabling it to recognize materials (paper, metal, plastic) even when they are severely deformed or cluttered.

Instance Segmentation: The model uses the Mask R-CNN algorithm to distinguish individual items on a moving conveyor belt, even when they overlap.

Taxonomy of Materials: It utilizes a customized taxonomy that categorizes items by both material type (e.g., metal) and material form (e.g., can).

High Precision: Pilots have shown detection accuracy of over 90% for metals and various plastics.

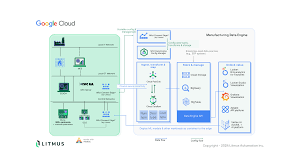

2. Technical Architecture: Edge to Cloud

Building this system requires a bridge between physical hardware (cameras on a conveyor) and cloud-based analytics. Google Cloud’s Manufacturing Data Engine (MDE) serves as the foundational architecture.

Component | Role in the System |

Manufacturing Connect | An edge platform that connects cameras and sensors on the factory floor, supporting over 270 automation protocols. |

Processes and contextualizes raw image data from the edge, storing it in a factory-optimized data lake | |

Used to host, fine-tune, and deploy the CircularNet models for real-time inference | |

BigQuery | Centralized repository for all historical data, allowing for trend analysis of "unwanted item" frequency |

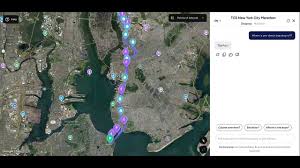

3. Predicting Unwanted Items with Maps & Analytics

The system does more than just sort; it predicts where contamination is likely to occur by leveraging geospatial data.

Geotagging Contamination: By mapping the origin of collected loads using the Google Maps Platform, facilities can identify "extremely high" contamination zones.

Predictive Trends: Analysis of weekly and daily trends reveals consistent hotspots for unwanted items, allowing municipalities to target education or incentives to specific neighborhoods.

Route Optimization: Using the Maps Mobility Services, facilities can optimize collection routes to separate highly contaminated loads before they enter the main sorting line.

3D Facility Mapping: The Photorealistic 3D Maps API can be used to create a digital twin of the recycling plant, tracking the physical flow of materials and identifying bottlenecks in real-time.

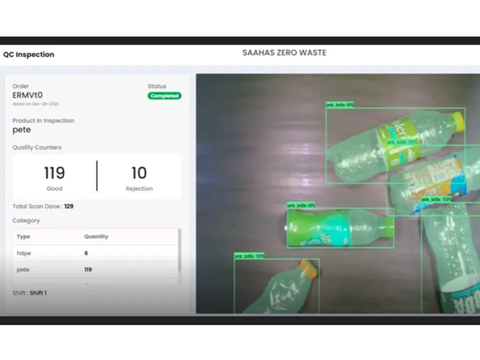

4. Case Study: Recykal’s Smart Skan

The Indian startup Recykal demonstrates the scalability of this architecture. They implemented "Smart Skan," which utilizes Google AI and CircularNet to process waste across 30 Indian states.

Ref link : Click here

Impact: They achieved over 90% accurate detection for metals and plastics.

Financial Gain: By removing contamination, they increased the value of the dry waste by approximately six times.

Scale: The system helps divert 50,000 metric tonnes of waste away from landfills every month

Conclusion

Building an AI-powered contaminant detection system is a strategic step toward safer, smarter, and more efficient metal recycling operations. By uniting CircularNet’s advanced computer vision capabilities with Google Cloud’s scalable MLOps infrastructure and Google Maps’ spatial intelligence, recyclers can move beyond manual inspection and achieve real-time, high-precision identification of hazardous and unwanted materials.

This technology-driven approach reduces operational risk, improves material quality, and enables continuous optimization across the recycling lifecycle. As demand for cleaner materials and stricter safety standards continues to grow, adopting intelligent, AI-enabled systems will be essential for facilities seeking long-term competitiveness and sustainability.

References

CircularNet: Reducing Waste with Machine Learning – Google Research

Vertex AI Documentation – Google Cloud

Google Maps Platform for Logistics & Transportation

Deep Learning-Based Waste Detection in Recycling

Comments